Protector bucal de EVA para bruxismo, 2-20P, Protector de dientes, bandeja bucal para rechinar, antironquidos, blanqueamiento dental, protección de boxeo - AliExpress

Runesol Ferula Descarga Bruxismo, 6 x Normal, Férulas Dental Moldeable, Protector Bucal para Dormir, Ferulas de Descarga para Bruxismo, Ferula Dental Noche, Funda Dientes, Felulas Bucales Dentales : Amazon.es: Deportes y aire

Protector bucal para rechinar dientes - Protector bucal para apretar los dientes por la noche, nuevo protector nocturno dental mejorado detiene el bruxismo para adultos y niños Bpa Free 2 | Fruugo ES

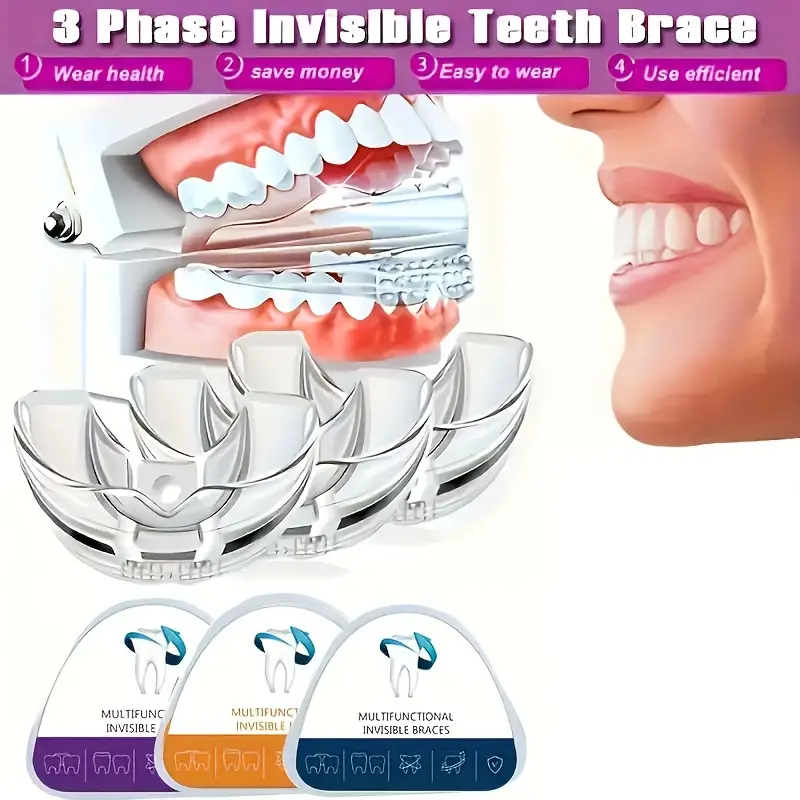

Correctores De Dientes De Ortodoncia Dental De 3 Etapas, Retenedor De Dientes, Protector Bucal Para Bruxismo, Soporte De Alineación De Aparatos Dentales, Protector De Dientes Transpirable Para Dormir - Temu Chile

2 pzs, protector bucal dental, protector bucal, cuidado de la salud bucodental, protector dental para detener

Amazon.com: Protector bucal para niños para rechinar dientes, paquete de 4 protectores de dientes para dormir por la noche, elimina la ATM y el apriete de los dientes, detiene el bruxismo, bandeja

Runesol Ferula Descarga Bruxismo, 12 x Mixto, Férulas Dental Moldeable, Protector Bucal para Dormir, Ferulas de Descarga para Bruxismo, Ferula Dental Noche, Funda Dientes, Felulas Bucales Dentales : Amazon.es: Salud y cuidado

Alineador Dental Ortodóntico De Tres Etapas, Aparato Corrector De Dientes Con Retenedor, Enderezador De Dientes, Protector Bucal Para Bruxismo Y Protector Dental - Temu Chile

Protector Bucal Para Dormir Guarda Dental Moldeable Bruxismo (2 piezas) : Amazon.com.mx: Salud y Cuidado Personal