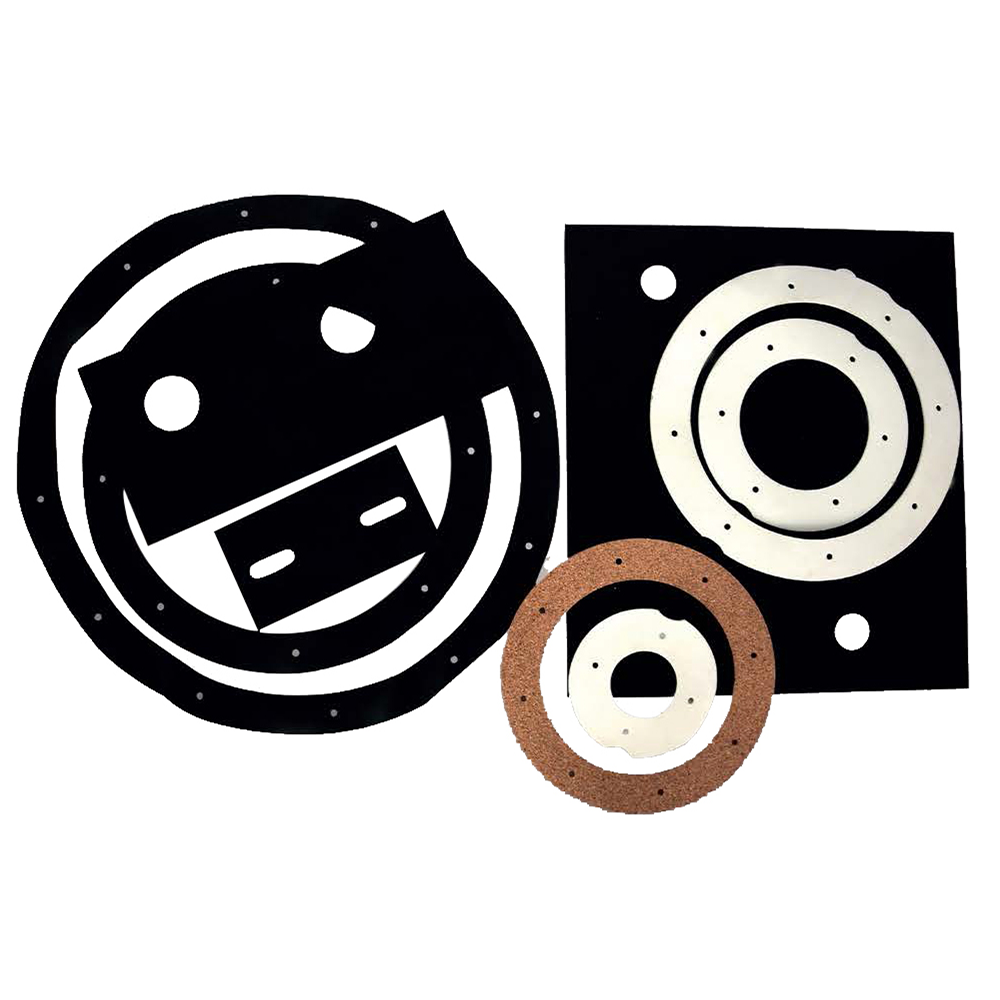

Diamond Die Cut Foam and Gaskets

Diamond Die-Cut Foam is a closed-cell polyethylene foam which is die-cutted into customized shapes and sizes. It is being used primarily for gasket purposes which effectively seals against air, dust and moisture.

- Customized die-cuts for effective sealing.

- Closed-cell foam structure.

- Excellent thermal stability.

- Foam can be coated with adhesive as per requirement.

- Can be applied to rough and uneven surface

- Recommended for gasket applications.

- Used for sealing & gap filling.

- Used for cushioning, isolating and vibration dampening.

- For packaging purposes. • For electrical, thermal and acoustic insulation.

Foam / Backing | Total Thickness | Unit | Adhesive | Color | Liner |

NBR | 3 to 25 / ± 0.75 | mm | Hot melt | Black | Laminated white paper |

PE Foam | 2+/- 0.5 | mm | uncoated | Grey | White paper |

NBR | Unit | Specifications | Test Method |

Foam Thickness | mm | 3 to 25 / ± 0.75 | ASTM D - 3652 |

Adhesion to Steel | g/inch | > 700 | ASTM D - 3759 |

Foam Density | kg/m³ | 60 ± 5 | ASTM D - 1622 |

Hardness (00) | mpa | 50 ± 2 | ASTM D - 2240 |

Temperature Range | ℃ | -5 to 55 | - |

Application Instructions:

Before applying, the surface must be free from oil, solvent, water and dust. For best product performance, apply the tape at room temperature between 15°C and 35°C.

Storage:

Store under normal room temperature and 50% RH in the original packaging

Product Expiry:

Use within 12 months from the date of manufacturing.

Note: The values provided above are results of standard lab tests and are subject to variations. Users are to determine the suitability of the product for its intended purpose.