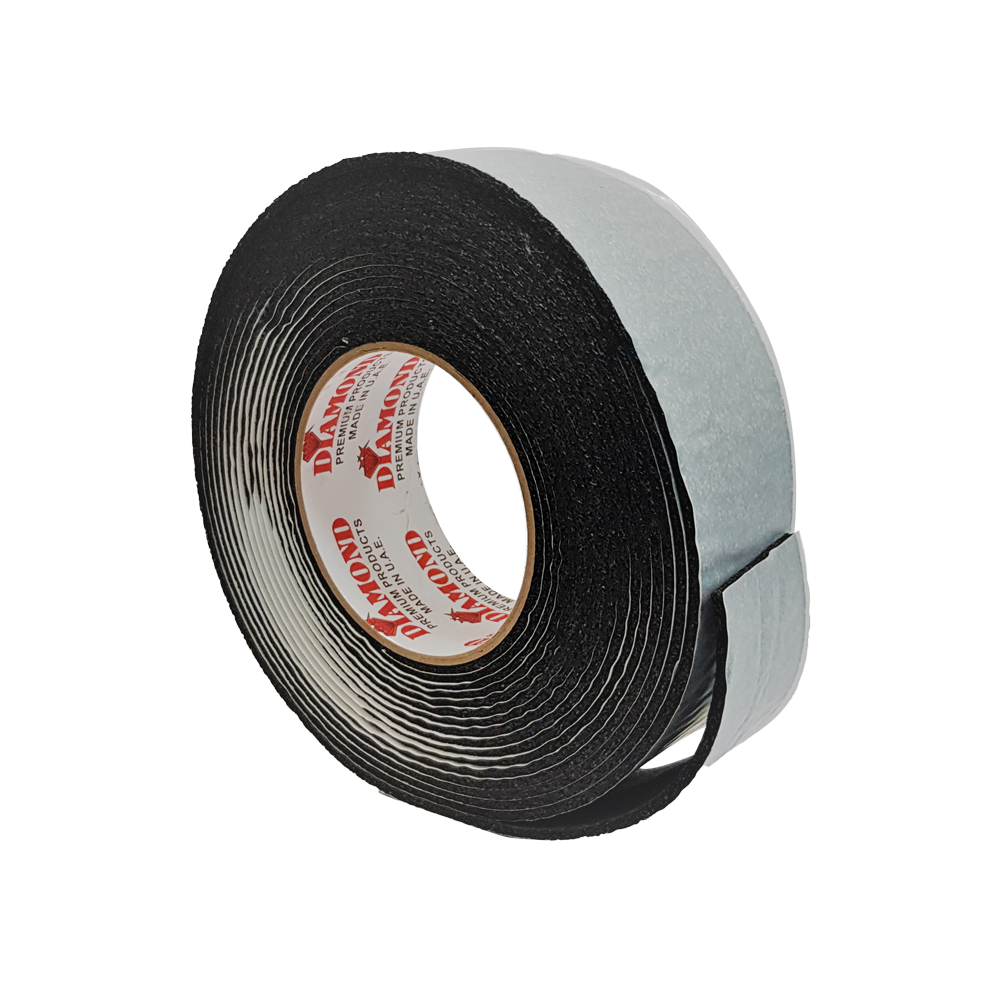

NBR Foam Tape – FR Grade

Diamond NBR (Nitrile Butadiene Rubber) Foam Tape consists of a soft & flexible closed-cell NBR foam coated with a medium strength acrylic adhesive and laminated to a white HDPE release liner. The tape has excellent flexibility which is suitable for thermal insulation and duct gasket purposes.

- Fire Rated: ASTM E84-16 Test Standard.

- Excellent flexibility & conformability to a wide variety of surfaces.

- Provides a very good service temperature range.

- Adheres well to a variety of surfaces.

- NBR foam tape can be used for hot or cold pipe wrapping.

- Recommended for insulation purpose due to its high flexibility and conformability.

- Used for gasket purpose.

- NBR foam tape will act as a water and air/dust seal when compressed.

- Used for refrigeration, air conditioning and other related applications.

Properties | Unit | Specifications | Test Method |

Backing Thickness | mm | 3 ± 1 | ASTM - D3652 |

Adhesion To Steel | g/inch | ≥ 800 | ASTM - D3330 |

Tensile Strength | N/inch² | ≥ 450 | ASTM - D3759 |

Elongation at Break | % | ≥ 155 | ASTM - D3759 |

Density | kg/m³ | 60 - 70 | -ASTM - D1667 |

Temperature Range | ℃ | -5 to +120 | - |

ASTM E 84 - | 16 Fire Rating | ||

Flame Spread Index (FSI) | - | 0 | ASTM E84 - 16 |

Smoke Developed Index (SDI) | - | 0 | ASTM E84 - 16 |

Backing | Adhesive | Color | Liner |

NBR Closed Cell Foam 3 mm | Solvent Acrylic | Black | White HDPE |

Standard Sizes | ||

Width (mm) | Length (m) | Rolls / Box |

24 | 7.5 / 10 | 80/20 |

48 | 7.5 / 10 | 40/10 |

Application Instructions:

Before applying, the surface must be free from oil, solvent, water and dust. For best product performance, apply the tape at room temperature between 15°C and 35°C.

Storage:

Store under normal room temperature and 50% RH in the original packaging

Product Expiry:

Use within 12 months from the date of manufacturing.

Note: The values provided above are results of standard lab tests and are subject to variations. Users are to determine the suitability of the product for its intended purpose.