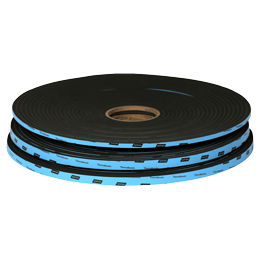

Thermalbond (Norton) Tape

Thermalbond (Norton) Tape is a high-strength, open- celled polyurethane foam spacer tape for structural glazing application.

- An open-cell structure allows air and moisture to reach the silicone for optimum curing of the silicone.

- Semi-rigid polyurethane foam is compatible with all kinds of silicone tested.

- Low thermal conductivity improves the performance of the wall and supports LEED points.

- Excellent resistance to temperature variations, fungi and oxidation.

- Easy removal of the liner even after glass is already positioned.

- Adhesive is UV resistant to minimize color change.

- Superb spacer for 2-sided & 4-sided structural glazing.

- Thermal break in window, door and wall systems.

- Bonding of wide joints.

Properties | Unit | Specification | Test Method |

Density | lbs./cu.ft (kg/m³) | 22 (352) | ASTM – D1667 |

Force to Compress | 10%:psi (kpa) | 16 (110) | ASTM – D1667 |

Hardness | shore A | 30 | ASTM – D2240 |

Tensile Strength | psi (kpa) | 130 (896) | ASTM – D412 |

Elongation | % | 105 | ASTM – D412 |

Dynamic Tensile Adhesion | psi (kpa) (15-minute dwell) | 45 (310) | NTP-11 |

Dynamic Shear Adhesion | psi (kpa) (15-minute dwell) | 30 (206) | NTP-5 |

Static Shear Adhesion | hours (hours @ RT) (7 kpa load) | 2000 + | NTP-57 |

Thermal Conductivity: K Factor | (BTU(in.)hr.ft2. oF (w/m oc) | 55 (0.08) | ASTM - C518 |

Migratory Staining of Acrylic Enamel | 200 hours of ultraviolet at 60℃ | No Staining | ASTM – D925 |

Recommended Service Temp. | ℃ | -40 to 80 | - |

Recommended Application Temp. | ℃ | 15 to 50 | - |

Backing | Adhesive | Color | Liner |

NBR Closed Cell Foam 3/6 mm | Solvent Acrylic | Black | Brown Release Paper |

Hot Melt |

Grade | Thickness (mm) | Length (m) |

V2204 | 3.2 ± 0.2 | 15.2 |

V2206 | 4.8 ± 0.2 | 15.2 |

V2208 | 6.4 ± 0.2 | 15.2 |

V2210 | 8 ± 0.2 | 7.6 |

V2212 | 9.5 ± 0.2 | 7.6 |

Application Instructions:

Contact surface must be thoroughly cleaned and dry. Once Thermalbond is applied, it cannot be removed and reused.It is important position the sections carefully, making sure that the product is in contact with all surfaces.

Storage:

Material should be stored at 70˚F (21˚C), 50% relative humidity.

Product Expiry:

Use within 12 months from the date of manufacturing.

Note: The values provided above are results of standard lab tests and are subject to variations. Users are to determine the suitability of the product for its intended purpose.